So strong it's kid-proof! We'll show you how to do it.

![]()

Time

![]()

Complexity

![]()

Cost

If you have a loose stair rail, a weak stair rail or no rail at all, fix the problem by installing a solidly anchored railing like we show here. Would your stair rail hold up to three energetic youngsters hanging on it like this? If you're not sure, or if you have stairways with missing rails, now's the time to fix the problem. More accidents happen on stairways than anywhere else in the house, and a strong stair rail goes a long way toward making stairs safer and easier to use. In this article, we'll show you how to cut and assemble your rail, how to mount it solidly to the wall framing and determine the proper handrail height.

The design we chose to replace stair railings lightly exceeds the building codes in many regions. We extended the stair railing beyond both the top and the bottom steps. While this isn’t always possible, it allows you to grasp the stair railing sooner and hold onto the stair handrail longer to maintain good balance. While you’re it, read about the important residential stair codes.

Before you go shopping for your handrails for stairs, measure from the nosing of the top landing to the floor at the bottom of the stairs and add 2 ft. This is the length of stair railing material you’ll need. You’ll find code-approved handrail and the other materials you’ll need at lumberyards and home centers.

Hardwood handrails for stairs like the oak stair railing we’re using are more expensive. Pine and poplar rails cost less. In addition to the stair railing, you’ll need wall mounted handrail brackets, a package of two-part, 90-second epoxy, and about 4 ft. of 2×4. Buy enough brackets to install two at the top, one at the bottom and one every 48 in. between the top and the bottom of the stair railing.

To replace stair railing, start by finding and marking studs. In order to be safe, handrails for stairs must be anchored securely to the wood framing behind the drywall or plaster.

Here are a few tips for locating the studs:

In addition to finding the studs, you have to make marks at the top and bottom of the stairway to indicate the standard railing height of the rail above the stairs. To meet building code requirements, the stair railing should be mounted so that the top of the handrail height is 34 to 38 in. above the front edge of the stair nosings. We chose 36 inches.

Locate the studs in the wall above the stairs. Use a stud finder and mark the locations with strips of 1-1/2 in. masking tape centered about 36 in. above the stairs.

Family Handyman

Plumb up from the front edge of the top stair nosing and stick a piece of tape to the wall. Make a vertical line even with the front of the nosing and a horizontal line at 36 in. Do the same at the bottom tread.

Later you’ll align the top of the rail with these handrail height marks and locate the rail brackets. Then you’ll use the mark at the top to position the rail before you attach it to the brackets.

Family Handyman

The next step is to cut the stair railing and glue on the short horizontal section at the top. Since the rail runs parallel to the stairs, you can use the stair noses as a guide for cutting the rail to the right length and figuring the top angle.

Start by cutting a 45-degree angle on one end of the stair railing and rest this end on the floor. This cut is for the short return to the wall.

Family Handyman

With the rail resting on the front of the stair treads, mark where the rail contacts the top stair nosing.

Family Handyman

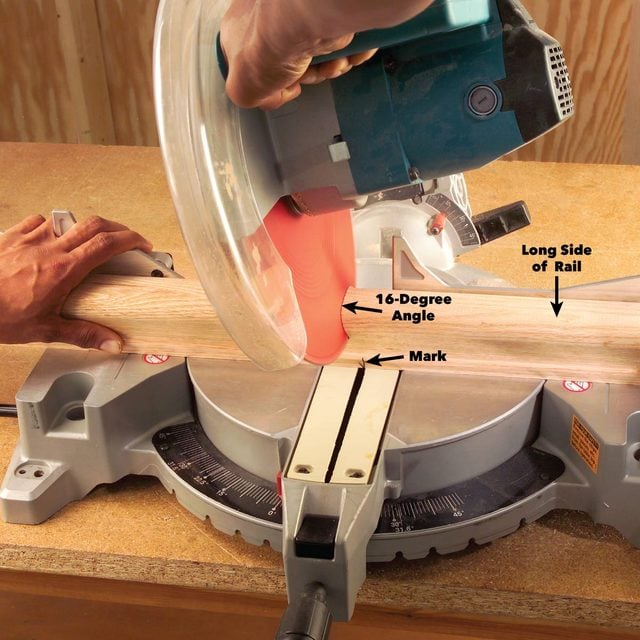

Set your power miter saw to cut a 16-degree angle and saw the rail at the mark. Cut the opposite 16-degree angle on the remaining rail piece. Use it for the horizontal top section. This is an approximate angle. You’ll test the fit.

Family Handyman

Test the fit of the rail joint. Adjust the cutting angle and recut both pieces until the joint is tight. Don’t worry if you lose a little length on the rail. It’ll just reduce the distance the rail extends at the bottom, which isn’t critical.

When you’re satisfied with the fit, cut the short horizontal stair railing section to length with a 45-degree miter on the end. Make it long enough to extend a few inches past the next stud so you can add a wall-mounted handrail bracket under it.

Family Handyman

The shallow angle makes it difficult to join the short and long stair railing sections with nails or screws. And dowels or other joining methods require a furniture maker’s precision. So instead we’ll show you a simple method to join the two with fast-setting epoxy.

Cut 2x4s on edge at the same angle as the rail and join them with screws driven at an angle. Then support the rail sections with the 2x4s as you press and hold the joint together. With 90-second epoxy, you’ll be able to hand-hold the joint together long enough for the epoxy to grab. Concentrate on keeping the profiles exactly lined up and pressing the rails tight together to eliminate gaps. Then leave the joint undisturbed for at least an hour. Overnight would be better, since the epoxy doesn’t approach maximum strength for at least 24 hours.

To protect the wood from epoxy that may ooze out, wrap the rail ends with masking tape. Trim excess tape flush to the cut end with a sharp utility knife. Then carefully remove the tape after the epoxy has set for five minutes. The finished joint will probably require sanding to even up the edges. Do this after the epoxy hardens.

Family Handyman

Align the top of the handrail with the 36-in.-high marks on the tape (see close-up photo, below), and mark along the underside of the rail at each stud location for the handrail height.

Family Handyman